Clicheria DP Studio elevates flexo platemaking with XSYS ThermoFlexX Catena-E 80: A leap towards quality and sustainability

Indice

Clicheria DP Studio has upgraded its flexo platemaking capabilities with a ThermoFlexX Catena-E 80 high performance exposure frame from XSYS. Installed to deliver best-in-class quality to its customers, the new equipment has exceeded the expectations of the Brazilian prepress company.

Clicheria DP Studio, founded in 1990, serves customers in the label and flexible packaging sectors with photopolymer plates for flexo printing. Based in Londrina, in the northern region of Paraná, Brazil, the award-winning prepress provider is known for its high level of skill and professionalism. The operations cover the whole country, as well as Bolivia and Paraguay, always maintaining its ethical principles and search for quality in all its products.

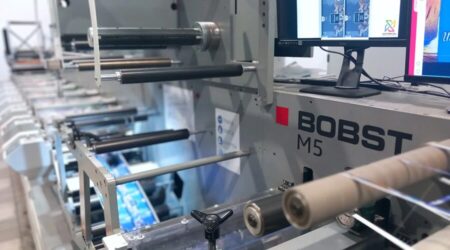

To maintain its leading edge, DP Studio continually seeks out the best technologies, installing state-of-the-art equipment for imaging and processing flexo plates. In a new partnership with XSYS, DP Studio has brought in a ThermoFlexX Catena-E 80 exposure frame, which utilizes the latest technology UVA LEDs for both main and back exposure, ensuring accurate image reproduction, stable flat-top dots, and guaranteed repeatability. This investment complements the customer’s current use of XSYS plates, specifically the nyloflex® NEF. The nyloflex® NEF is a high durometer plate optimized for LED exposure technology like Catena-E, offering excellent flat top dot creation, improved ink lay-down, and high solid ink density.

“The new ThermoFlexX Catena-E 80 has already surprised the whole team due to the robustness and the performance, which exceeded initial expectations,” said Agnaldo Moraes, Technical Commercial Manager at DP Studio. “The first jobs we put through the machine quickly demonstrated the improvements that can be achieved with Catena exposure, particularly in the highlight areas. Furthermore, we’re also saving time and energy.”

High quality and sustainable platemaking

With 70 employees, DP Studio prides itself on the quick supply of plates, created to the exact requirements desired. The large design team works closely with customers, finding a personalized solution that will deliver their packaging vision, as well as cooperating with the machine operators to ensure that the plates will print exceptional quality. The new Catena unit allows DP Studio to expand these capabilities and offer even more advanced solutions while also contributing to sustainability.

The ThermoFlexX Catena-E 80 provides high-performance LED exposure – perfect for imaging the finest surface microstructures such as Woodpecker Nano. Processing plates in sizes up to 1270 x 2032 mm (50 x 80”), it also utilizes LEDs for the back exposure, ensuring consistent and even floors across the entire plate.

Not only does LED technology produce the most consistent and precise flat-top dot plates, it also reduces the carbon footprint of the platemaking process. LEDs require no warmup, meaning less energy is consumed, and last longer than conventional lamps, thereby minimizing toxic waste. In fact, the LEDs in the Catena system have been fully tested to 10,000 operating hours and beyond.

Future-proofing with Catena and XSYS support

Built as an open system, the Catena-E 80 has easily slotted into DP Studio’s current workflow. It features an intuitive Graphic User Interface (GUI), running the latest Windows OS, with a Full HD touch-screen, making operation extremely fast and simple.

“We chose the Catena-E 80 LED exposure unit because of the many benefits it brings, including guaranteed stable quality, optimized speed, ease of operation, and lower environmental impact. This means we can better meet the many demands of our customers,” stated Marcos Balestra Industrial Manager at DP Studio.

Another important aspect is the modular design of the exposure frame. It has been created for seamless integration with other Catena modules, enabling a path to complete automation in platemaking. “Naturally, we always have an eye on the future, so the option to expand into a fully automated platemaking line also appealed when we were researching the market,” said Domingos Rocha Director of DP Studio.

He concluded by stating that the choice to create this new partnership with XSYS was not made entirely based on the quality of the Catena products. He highlighted the commercial and technical services offered by the company, including the expertise of its technicians and extensive remote support service capabilities.