Kongsberg Precision Cutting Systems elevates CNC routing standards with launch of new MultiCam Apex3R Evo

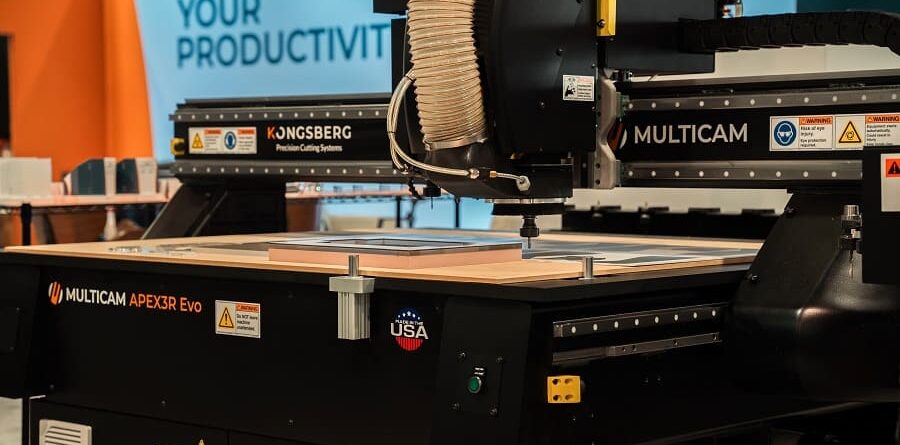

Kongsberg Precision Cutting Systems (Kongsberg PCS) has September 10 unveiled the latest evolution of its flagship MultiCam Apex3R CNC router, raising the bar for superior quality and signalling a new era in high-performance routing capabilities.

Engineered for a broad array of applications, the new MultiCam Apex3R Evo combines incredible versatility with superior cutting precision, all at a competitive price. The new machine extends its cutting abilities across both flexible and dense materials, significantly enhancing operational efficiency. It ensures sharp, precise edges and effortlessly achieves mirror-like finishes on aluminum and polished edges on thick acrylic.

Launched at the PRINTING United event in the U.S. – the home of MultiCam, where the brand is celebrating 35 years of success – the introduction of the Apex3R Evo underscores Kongsberg PCS’ commitment to delivering top-tier technology worldwide and meeting the demands of the EMEA region.

“This new MultiCam model is particularly geared towards signmakers who require professional CNC capabilities,” said David Preskett, Kongsberg PCS Vice President of EMEA and APAC. “With its perfect balance between performance and precision, the Apex3R Evo sets a new standard for routers. With the addition of features like a new surface probe and pneumatic vacuum zones, this already robust CNC machine now delivers even more than pristine cut quality and precise accuracy for which it is renowned.”

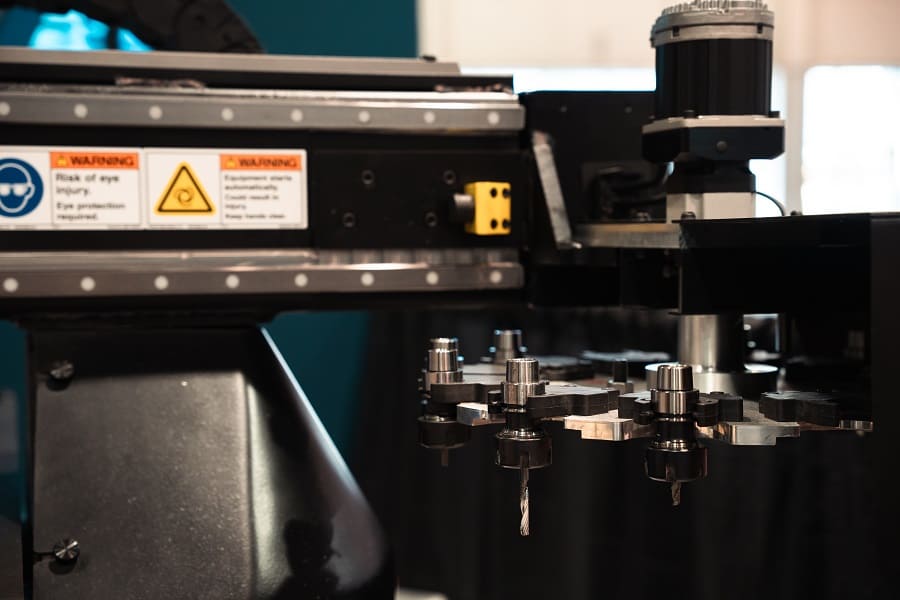

The Apex3R Evo features a newly designed condensed knife system, upgraded tapping features to simplify and streamline production, and an improved dust boot providing better particulate pick-up and operator-friendly quick-change bristles or glide pad. Collet and ATC spindle options range from an impressive 24-32K RPM and up to 13.3 HP, making the Apex3R Evo suitable for a wide range of jobs using different tools and materials.

“The innovative condensed knife system delivers improved cut quality, with a new electric oscillator knife that can be configured between 2mm and 5mm stroke to tackle any cuttable material,” said David. “Our upgraded pneumatic ‘Quick Change’ knife body allows for both knife and tapping tool change capabilities, enabling users to use multiple tap sizes in one job and reduce secondary processes, achieving perfect tapping depths with greater efficiency through automation.

“Importantly, the Apex3R Evo is also modular, allowing businesses to add our knife and/or rotary tool changer as needs evolve,” he said.

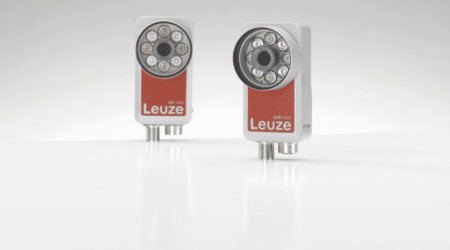

The Apex3R Evo also introduces a new high resolution registration camera with improved lighting which ensures register marks are located accurately and more reliably, improving production efficiency. “The MultiCam EZ Control operator interface, included as standard, ensures businesses can start routing right away with minimal interruption to work processes,” added David.

The Apex3R Evo is designed to cut a wide range of materials such as plastic, aluminum, wood, high-density foam, and composites. “The Apex3R Evo is as robust as it is versatile,” said David. “The all-welded steel frame is precision-engineered to enhance its cutting accuracy while minimizing vibrations, resulting in cleaner and more precise cuts.”

The MultiCam Apex3R Evo was launched today at PRINTING United, which runs from 10-12 September at the Las Vegas Convention Center, Nevada.

For more on the new MultiCam Apex3R Evo and the entire range of MultiCam CNC solutions, visit www.multicam.com