A new plant for CMP Phar.ma. Maurizio Marchesini: “We’re investing in the Veneto region and opening the way to production with AI”

– An investment of seven million Euros. A new site of 5 thousand new square metres, more than half to be used for production. And a doubling – from today’s 42 to 80 – of the workforce in four years. These are the main figures that denoted the inauguration of the new plant of CMP Phar.ma of Costabissara (Vicenza, Italy), a company that specialises in the production of inspection systems for the pharmaceutical industry.

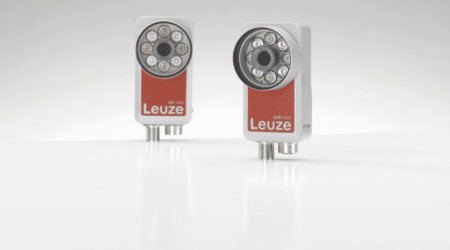

As far back as 1982, little more than 10 years after its incorporation, CMP Phar.ma was one of the first companies to introduce an automatic ampoule inspection machine with laser lighting onto the market. Over time, CMP Phar.ma has consolidated its position by perfecting a product portfolio which today includes a huge range of inspection machines, not only for ampoules but also for vials, pre-filled syringes and freeze-dried products.

Its recent entry into the galaxy of companies controlled by Marchesini Group – the Bologna-based multinational that is one of the world’s leading producers of machines for packaging pharmaceutical and cosmetic industry products – is enabling CMP Phar.ma to contribute its inspection machines to the realisation of entire production lines, including those used by Big Pharma for packaging Covid vaccines and cancer drugs, both types of biological drug requiring an extremely high level of quality control.

The inauguration was attended by Barbara Beltrame, Vice President of Confindustria with responsibility for internationalisation, and Giovanni Maria Forte, Mayor of Costabissara.

The house honours fell to Luigino Pilastro, CEO of CMP Phar.ma, and Maurizio Marchesini, Chairman of Marchesini Group. The new plant also received a blessing from Father Roberto Xausa, Parish Priest of Costabissara.

“The new plant will become the heart of the production operation, while the warehouse and the company’s Research and Development department will remain at the current site nearby,” Luigi Pilastro explained. “At both sites we will work to conceive and produce new inspection machine models to complete the range, to enable us to break into important markets such as North America and China. At the same time, we’ll push ahead with development of our programme based on Artificial Intelligence.”

The reference here is to the futuristic project developed by an in-house team in partnership with Eyecan, an innovative spin-off linked to the University of Bologna, in which Marchesini Group has a stake. The aim of this ambitious project – which will start to produce the first demos as early as 2024 – is to introduce Artificial Intelligence as standard on all inspection machines.

“At CMP Phar.ma and within Marchesini Group, we make use of AI algorithms both for the predictive maintenance of our machines and to improve the vision and inspection systems used during packaging cycles, as well as to increase the intelligence of the robotics needed to handle products on our lines,” Maurizio Marchesini explained. “The already impressive results are helping to improve production quality and to release human beings from repetitive tasks and free them up for more ‘human’ jobs. So when people ask me – also in my role as Vice President of Confindustria – whether technological progress will create unemployment, my answer is nuanced: jobs will certainly be lost, but new professions will emerge. The crucial difference will be between those working with neural networks and those not capable of using them.”