European container glass industry is decarbonising glassmaking

Indice

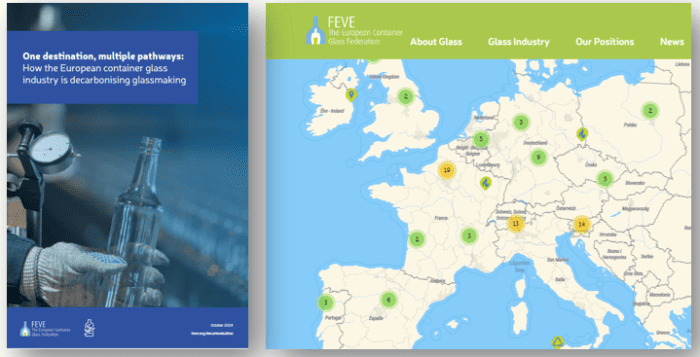

The European container glass industry has published its landmark report (1), marking the first and most comprehensive industry-wide research detailing the steps being taken to decarbonise glass manufacturing. The report is accompanied by a dedicated section on the FEVE website, including an Online Map with over 90 industry case studies showcasing decarbonisation efforts across Europe.

While the industry is fully committed to this transformation, it cannot achieve its ambitious goals alone. Collaboration is essential for the container glass industry to deliver a packaging solution that is not only fully circular but also climate-neutral.

Urgent Need for Access to Affordable Low-Carbon Energy

A crucial step in reaching the industry’s net zero goal by 2050 is rapid access to affordable, low-carbon energy. Currently, 80% of the glass container industry’s direct carbon emissions result from the combustion of natural gas. Switching to low-carbon energy sources is therefore a top priority. More than 90% of the glass containers produced in the EU are made by companies that have committed to the Science-Based Targets initiative (SBTi).

EU Support with New or Existing Financial Instruments is Critical

The access to new financial instruments or the continuation of existing ones to support the industry efforts in the transition is also essential. As glass furnaces have a lifespan of 10 to 15 years and an estimated annual replacement rate of 7% to 10%, it is imperative that old furnaces are gradually replaced with ones that can operate using low-carbon technologies. The window for action is now, to ensure the sector reaches its 2050 net zero target. Currently, the glass container industry invests over €600 million annually in innovation and decarbonisation, including efficiency and plant upgrades. To fully achieve net zero, an estimated €20 billion in additional capital expenditure will be required by 2050 to upgrade production technologies and decarbonise operations. This is a conservative estimate that excludes increased operational costs tied to securing and using low-carbon energy sources.

Glass: A Reliable Partner for a Sustainable Future – Continued Trust is Needed

Glass container manufacturers remain resolutely committed to overcoming the decarbonisation challenge, meeting growing customer demand for low-carbon glass, and positioning glass as the sustainable packaging material of the future. As a permanent material that can be recycled infinitely without losing quality, glass boasts an impressive collection rate in Europe—80.2% in 2022—with most of the material being recycled in the closed-loop. Additionally, glass is a safe packaging material that does not leach harmful chemicals into products, regardless of how many times it is recycled.

Glass is a permanent material that can be recycled infinitely without losing quality and is a safe packaging material that does not leach harmful chemicals into products

The industry calls on its customers to continue trusting and choosing glass as a key packaging solution, joining us on this transformative journey to a sustainable future.

An Essential Material for Essential Services

With 162 glass manufacturing plants spread across Europe, the glass container industry supports 125,000 direct and indirect jobs. Moreover, over €140 billion worth of EU exports are packaged in glass, while an estimated 45,000 manufacturing companies across the EU rely on glass packaging to sell their products—98% of which are SMEs. The role of glass in the pharmaceutical, food, and beverage, as well as perfumery and cosmetic sectors is critical, and it remains an indispensable packaging material.

(1) To discover more about the industry’s ongoing decarbonisation projects and innovations, download the full report.