FCE Pharma: Marchesini Group focuses on blister technology and multimedia. A Print&Check solution is also on show

From 30 November to 2 December, one of the most important events for the pharmaceutical sector in Latin America is back: FCE Pharma 2021. For the occasion, Marchesini Group will attend São Paulo Expo with an original stand inspired by the football world, a symbol of the philosophy that has always guided the Group’s work: taking action to guarantee assistance and satisfy customer needs in the shortest possible time, working together to achieve extraordinary results.

Stand G059 in Hall 1 will be full of multimedia installations: the focus of this edition will be on the most innovative technologies developed by the Group in the field of blister packaging for solid products, which will be projected on a large screen. The public will be able to discover solutions designed to meet the needs of the growing South American market.

Drawing on over 40 years of experience, the Group can offer a number of solutions to safely manage the entire blister product packaging process, from the moulding of the cavities to the end of line. There will be a specific focus in particular on INTEGRA solutions: monobloc, robotised, integrated packaging lines consisting of a blister packaging machine and cartoning machine that can produce 200 to 720 blisters/min and 100 to 500 cartons/min.

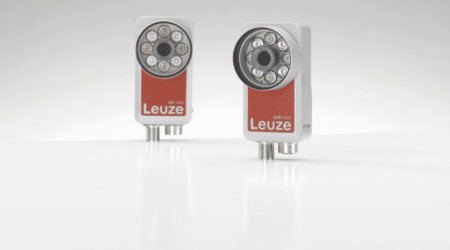

These lines feature an integrated robot, designed in-house, which allows blisters to be transferred directly from primary to secondary packaging, while maintaining a compact design. These solutions are also equipped with the most important technologies in the field of vision systems: from verification of the integrity and quality of the product contained within the blister to the most sophisticated controls for checking the active ingredient contained in them, an increasingly important requirement in the pharmaceutical sector.

At FCE Pharma, the Group will also be exhibiting the BL-A309 produced by the Neri Division: a versatile solution for Print&Check and serialisation operations that makes it possible to quickly install all the main pharmaceutical traceability devices available on the market, from laser printers to ink-jet technologies.

Main features of the BL-A309:

- Designed for easy access, inspection and maintenance

- PC control with ‘Fail Safe’ function

- Continuous speed control

- Patented carton indexing device

- The machine can accommodate one labelling head

- Automatic speed synchronisation of all motors and fast size changeover