New Bottles From Old Bottles: Economical and FDA-Compliant Recycling of PET Flakes

Innovative Process for Bottle-to-Bottle Recycling

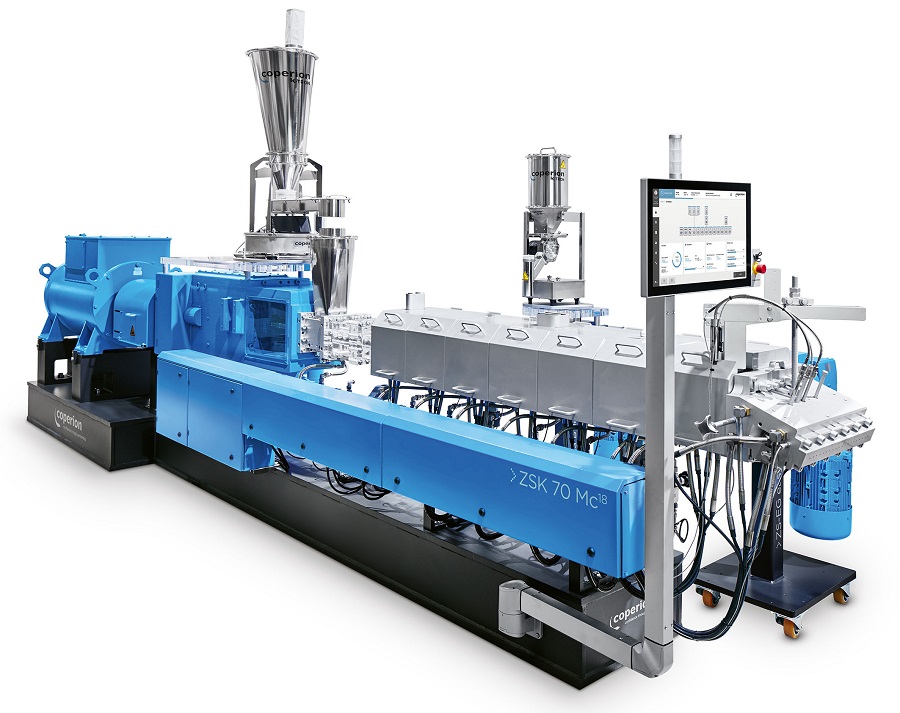

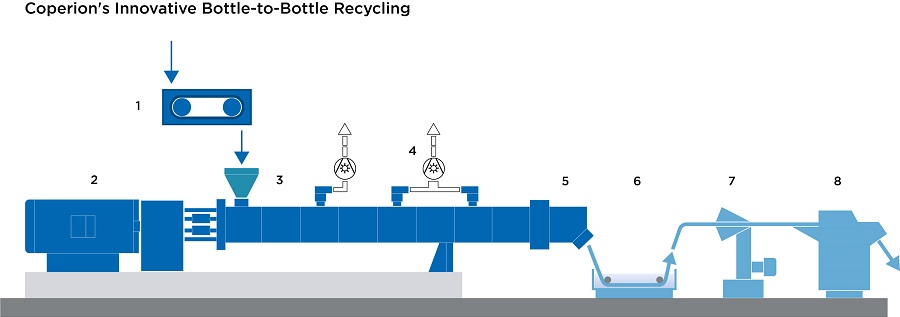

Polyethylene terephthalate (PET) is a high-value material that is on course to take over a key function in the plastics industry’s path toward a circular economy. PET flakes can now be processed without pre-drying into pellets using Coperion ZSK twin screw extruders. Next they are condensed in the SSP (Solid State Polycondensation) reactor, and reprocessed back into bottles again with the quality of virgin material.

PET recyclate manufactured using this innovative process has received approval from the United States Food and Drug Administration (FDA) for food-contact uses. Thanks to the highly efficient plastification within the ZSK extruder, Coperion systems for this bottle-to-bottle recycling process achieve throughput rates between 2 and 8 tons per hour, therefore recycling companies profit from very high product quality, reduced operating and logistic expenses as well as from energy cost savings up to 30% in comparison to conventional PET recycling methods.

Bottle-to-Bottle Recycling Now Clearly More Efficient

PET plays an ever more important role in recycling, due to the large volume of packaging materials in use today. PET is a very high-value material, possessing extremely good properties for reprocessing. Its continuously expanding use in single- and reusable bottles, as well as its recovery via deposit systems, add to its value. Correspondingly, it can be lucrative for companies to focus on PET recycling.

Before PET can be reprocessed, it must first be shredded to flakes and then cleaned. Ordinary technologies require pre-drying, crystallization or agglomeration of the PET flakes following washing. However, using the specialized technology from Coperion, the shredded PET can be fed directly into the ZSK twin screw extruder and compounded.

The shredded flakes are reliably fed into the ZSK extruder using high-accuracy SWB (Smart Weigh Belt) feeders or gravimetric feeders from Coperion K-Tron. In addition, other regrind materials, new materials, or mixtures can be added. Melting, intensive devolatilization, and complete homogenization take place in the ZSK process section before the melt is transferred via a gear pump and filter with an automatic screen pack changer to a strand or underwater pelletizer for pellet production.

The shredded flakes are reliably fed into the ZSK extruder using high-accuracy SWB (Smart Weigh Belt) feeders or gravimetric feeders from Coperion K-Tron. In addition, other regrind materials, new materials, or mixtures can be added. Melting, intensive devolatilization, and complete homogenization take place in the ZSK process section before the melt is transferred via a gear pump and filter with an automatic screen pack changer to a strand or underwater pelletizer for pellet production.

Pellets are then condensed in an SSP reactor. The pellets’ quality meets the requirements of virgin material. They have received FDA Letter of Non Objection which certifies that they meet the standards for food-safe plastics and thus, can be processed into bottles once again.

With this direct processing of PET into bottles, recyclers profit particularly from the very high end product quality. Product handling in the bottle-to-bottle process is very gentle. The residence time in the ZSK extruder is very short and dispersion is very good. The ZSK extruders’ high torque enables processing at low temperatures and with almost no viscosity loss. ZSK extruders’ self-cleaning enables rapid recipe and color changes. Thanks to the ZSK twin screw extruder’s very good devolatilization options, volatile components such as monomers, oligomers, and water are reliably removed and channeled away from the exhaust flow in suitable separators before discharging the process section.

Alongside the high product quality, direct processing of PET flakes offers further advantages including reduced operating costs and energy consumption as well as lower logistic expense. Jochen Schofer, Business Segment Manager, Recycling & Direct Extrusion at Coperion added: “With FDA certification, we have officially confirmed the high product quality of the PET recyclates. With the Coperion solution, we make a technology available to recyclers that is economical and at the same time allows them to make a decisive contribution to the plastic industry’s path towards a circular economy.”