PCR in cosmetic packaging? It’s all a question of technology

The blow molding specialist W.MÜLLER has tested two methods for the use of post-consumer recyclates (PCR) in packaging. In the first examined variant, the PCR layer is surrounded by two layers of new material, the second variant is shielded with an internal plasmacoating. Both variants had significantly lower migration values than hollow bodies made of pure PCR.

W. MÜLLER has many years of experience with the use of PCR for the production of hollow articles in the blow molding process. With the in-house ReCo3 called 3-layer-co-extrusion system, bottles can be produced consisting of a PCR layer that is surrounded inside and outside by a virgin layer. In this way, virgin material can be replaced by PCR in processing, and still unwanted migration from the PCR can be reduced.

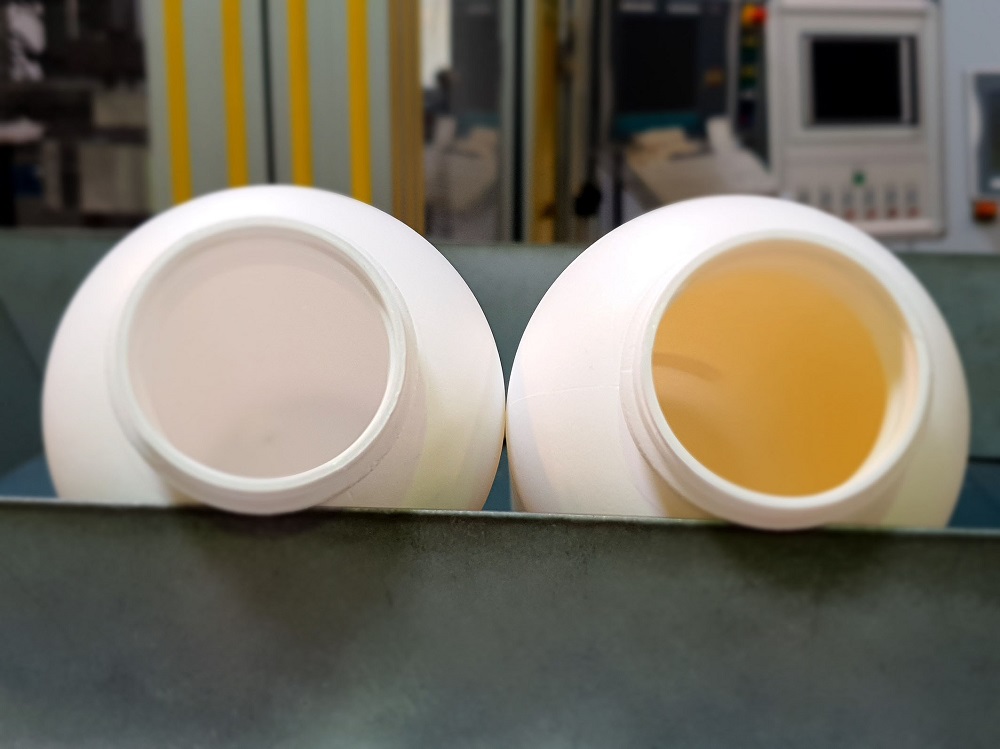

The company has tested how the migration behavior of round bottles with a volume of 1l from 100% recyclate differs from those produced with the ReCo3 process. Two certified PCR types were selected (one was Recylen BM 948-30, sponsored by OPG Holding, Teningen) and one bottle of the pure material and one with a virgin layer in the outer layer were produced. At the SGS INSTITUT FRESENIUS, Taunusstein, various migration tests were carried out, such as global migration and screening for potentially migratable impurities, reaction and degradation products (NIAS). Global migration was tested in accordance with DIN EN 1186 2002-07 and the results were in all cases below the legal requirement of Regulation (EU) No 10/2011 of 10 mg/dm2.

However, W. MÜLLER was able to show on the basis of the tests that the ReCo3 bottles show a lower global migration compared to the pure recyclate bottles. This is also confirmed by a significant reduction in the number and concentrations of migration-capable NIAS.

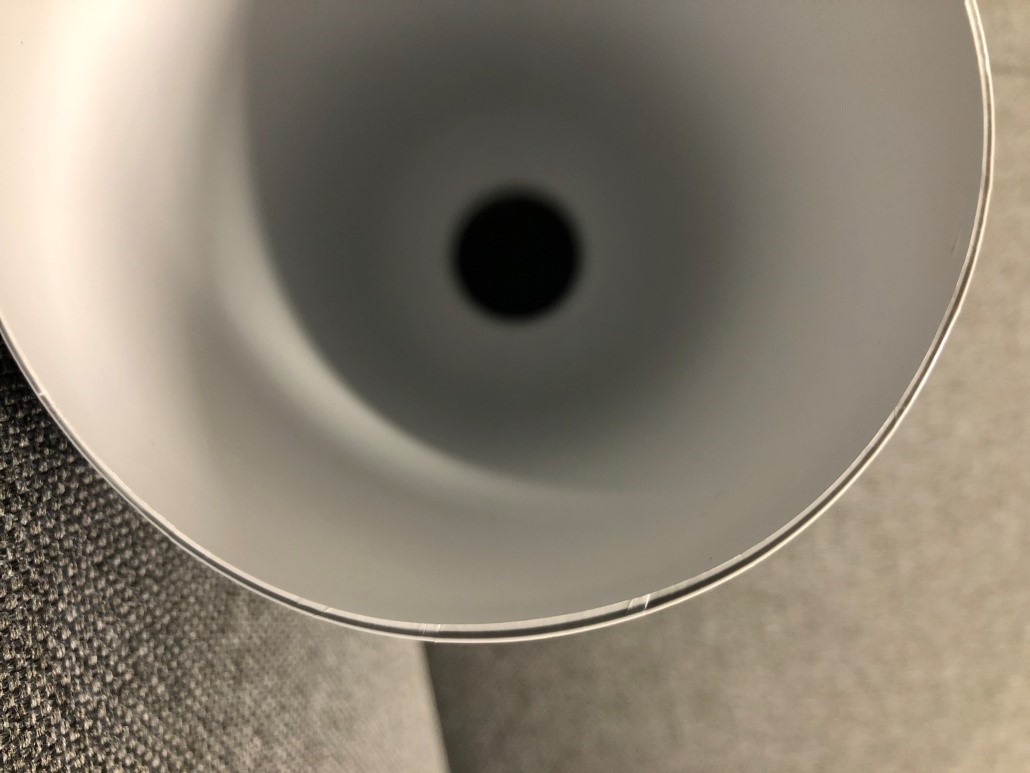

In order to increase the recyclate content in such three-layer systems, the surrounding layers must be as thin and yet stable as possible. In addition to plastic layers, plasma coatings are therefore also suitable for the purpose of shielding. In a second series of experiments, FABES Forschungs-GmbH, Munich, investigated how a CHF layer (CHF stands for carbon – C, hydrogen – H and fluorine – F) applied by the Belgian company Delta Engineering on the inside affects migration behavior. With the help of plasma, a barrier is created in the process. These bottles were made from Systalen 70000 na 002 HDPE, which was sponsored by Der Grüne Punkt.

The tests showed that the coating drastically reduces migration. While 76 substances were detected on the uncoated bottle, the CHF-coated bottle had only 5. Since fluorine is used for the CHF coating, additional tests have been carried out with the coated bottle to ensure that no residues have been formed. As a result, no substances can be detected. The bottles are therefore also compliant for direct contact with «Rinse-Off» products such as shower gel.

The involved research institutes point out that users have to carry out their own risk assessment, as the results depend, for example, on the size of the bottle and the intended use, and the starting materials could change from batch to batch.

Managing Director Christian Müller said: «We were able to show with the tests that the use of plastic recyclates for packaging of sensitive products is possible. With the right technology, there is no demonstrable risk of migration from the recyclate to the filling material. The findings confirm that our proven ReCo3 process fully meets these requirements. With the plasma coating we have tested another possibility of shielding. The results have encouraged us to offer this technology as a supplement in the future if customers are interested. Together with our partner Delta Engineering, we want to make it easier for our customers to use recyclates.»