TNA launches hydro cutting system for french fries at Anuga FoodTec 2024

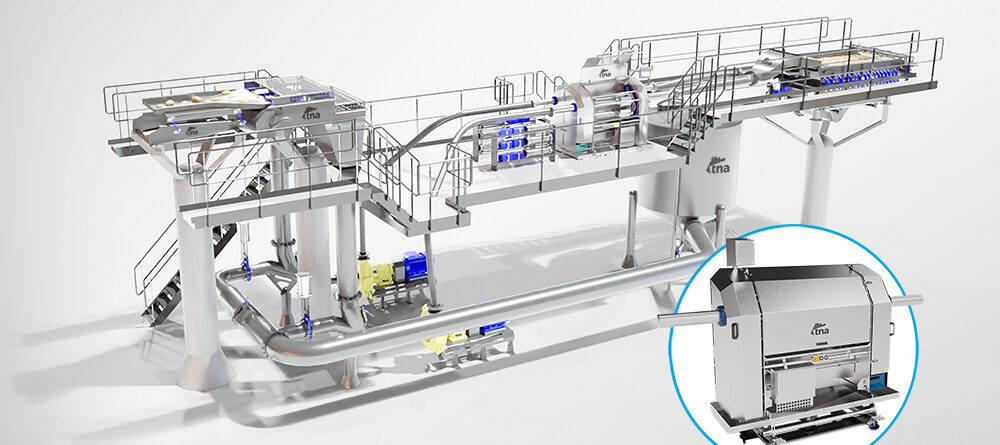

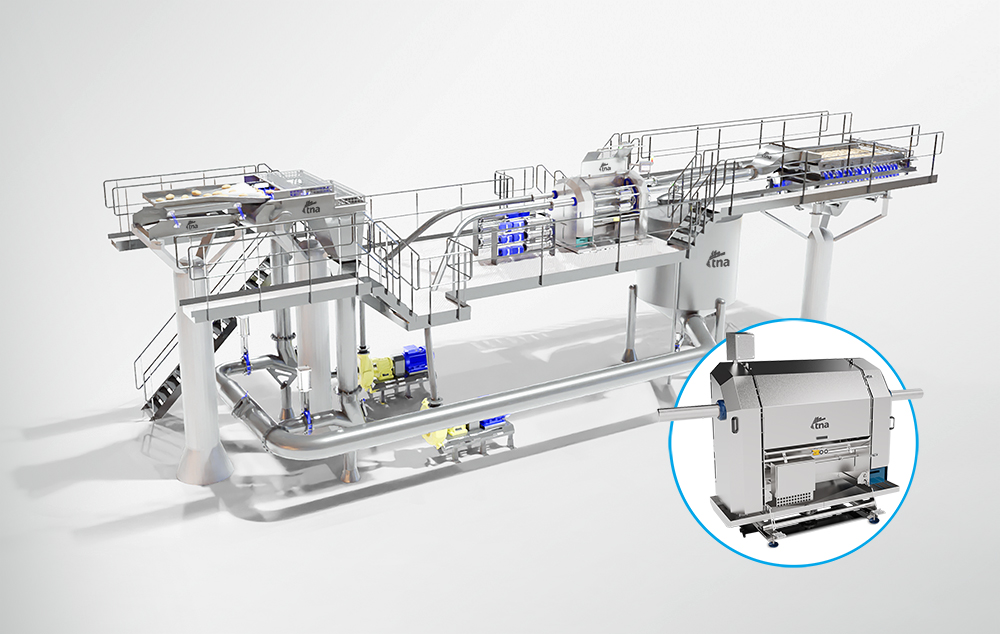

New tna conti cut® with innovative ‘switcher’ technology will boost capacity, efficiency and uptime for customers processing french fries.

TNA solutions has revealed its latest innovation in french fries processing, delivering greater efficiency, flexibility and consistency. The new tna conti cut® hydro cutting system, with cutting-edge ‘switcher’ technology, was unveiled at TNA solutions’ stand (Hall 10.1 | Stand E068) at Anuga FoodTec 2024. Visitors to the stand from now until 22 March can view the integral ‘switcher’ first-hand, which enables the hydro cutting system to easily deliver against the industry’s highest output capacity (approx. 30 Mt/hr).

“With the global french fries market set to grow to over $40bn in terms of value by 2027*, our customers require solutions that deliver maximum capacity and the highest levels of efficiency and uptime,” said Twan van den Berg, Global Sales Manager Processing at TNA solutions. “The new tna conti cut® has been designed to deliver against this incredible market growth, and we are proud to be displaying the innovative switcher alignment and cutting technology here at Anuga FoodTec.”

Switcher technology within the tna conti cut® delivers many benefits:

- Drive efficiency, productivity, reduced waste and uptime with designated alignment tubes and integrated knife blocks. Both are exchangeable, depending on the final product to be processed and potato size used.

- Achieve the longest cut size possible when processing potatoes in high volumes through the alignment tubes.

- Add flexibility with an interchangeable knife block, enabling potatoes to be cut into different shapes and sizes, such as: sticks, wedges, and slices.

- Guarantee a smooth cutting surface with the tna conti-cut® hydro cutting system, resulting in less oil pick up compared to a mechanically cut surface, reducing oil usage and fat content.

- A blockage is detected by means of a pressure transmitter or flowmeter installed in the switcher (e.g. broken knives / product stuck in knife block).

- Maintain uptime as the switcher automatically rotates the revolver to a new alignment tube and knife block, allowing the operator to take out the clogged knife block and replace the knives.

“Compared with a mechanical cutter, where centrifugal force is used to drop potatoes randomly onto a high-speed rotating cutting head, the tna conti cut® hydro cutting system uses the alignment tube within the switcher to ensure the potato is consistently positioned lengthways to produce a longer cut,” said van den Berg. “If we take strips as an example, this longer cut is vital when supplying customers such as quick service restaurants, that require the longest strips possible. The hydro cutter also creates a smoother throughput, which reduces oil usage, delivers a lower fat product and at the same time increases efficiency.”

Working with TNA experts to determine the correct configuration for a specific french fries processing line is highly recommended. The process and technical expertise they can provide, along with a customer’s in-depth knowledge of their operation, will ensure the resulting solution delivers above and beyond expectations.

“What we are demonstrating at Anuga FoodTec, in addition to this cutting-edge innovation, is our in-depth understanding of the balance required to satisfy consumers and retailers, while keeping brands profitable,” added van den Berg. “We use our capabilities, expertise and portfolio to deliver complete line solutions in partnership with our customers, drawing on our deep process knowledge to ensure any new technologies can be integrated with minimal operational disruption and maximum impact.”

Visit TNA solutions at Anuga FoodTec this week to see the ‘switcher’ technology first-hand (Hall 10.1 | Stand E068)

* Source: GlobalData (Retail & Foodservice Combined Figure)

Visit www.tnasolutions.com or contact tnateam@tnasolutions.com to learn more.